Lianhuo Expressway Zhongmu section Xubeigou Bridge expansion joint repair

Bridge Expansion Joint Rapid Repair Compound

Category:

Detailed description:

Introduction: Ultra-early high-strength rapid structural repair material is a kind of ultra-early high-strength repair material made of cement as the basic binder, early strength materials (quartz sand) as the main aggregate, and high molecular mineral powder, high-efficiency water reducer, early strength agent, and expansion agent, etc. It has the characteristics of ultra-early strength, no shrinkage, and good self-compaction.

Performance: Our company, through optimized design and ratio, uses mineral admixtures such as mineral powder as cementitious materials without weakening product performance, reduces the amount of cement, follows the principles of green environmental protection and sustainable development, and reduces costs at the same time.

The developed polymer rapid repair material has good workability, with a truncated cone flow of around 300mm.

The compressive strength at 2h is 24.3MPa, the compressive strength at 1d is 32.8MPa, and the compressive strength at 28d can reach as high as 70MPa. It has high early strength. The mechanical properties of the developed polymer rapid repair material are far higher than existing products on the market. At the same time, it can be divided into multiple series according to product performance and application, which are:

1) Repair of bridge deck expansion joints

2) Repair around road manhole covers

3) Treatment of bridge deck cracks

4) Rapid repair of broken concrete pavement

5) Treatment of bridge deck potholes

6) Rapid repair of severely damaged parts of concrete structures

Construction methods:

1. Base surface cleaning: Use a steel wire brush to thoroughly remove loose materials from the original concrete base surface, and use an air compressor to blow away the dust.

2. Base surface wetting: Wet the base surface with water 2-3 hours before pouring and remove standing water; during winter construction, the base surface should be wetted with warm water not exceeding 65℃ before pouring and standing water removed.

3. Mixing: According to the actual repair area and repair speed, manually put the repair material into a forced-type mortar mixer, dry mix for 10 seconds, and add the specified amount of water in two times: add 2/3 of the water for the first time, mix for 30 seconds; add the remaining 1/3 of the water for the second time, and mix for 150 seconds. In winter construction, warm water not exceeding 65℃ should be used for mixing, and the temperature of the mixed material should be above 10℃. The water-cement ratio is 16±1%.

4. Repair: Use a trowel or spatula to apply the repair material in layers and evenly to repair the damaged surface smoothly and compactly. The repair material from the start of mixing to the end of repair should not exceed 30 minutes. The repair material that exceeds the time or whose workability does not meet the construction requirements should not be used.

5. Curing: Cover the top surface of the repair material with plastic strips, and then cover the plastic strips with grass bags to keep it moist. At normal temperature, curing can be ended after 3-4 hours, or the decision on whether to end curing can be made based on the structural strength requirements and the results of the reserved sample strength test. In winter, insulation measures should be adopted, and the curing period should be appropriately extended.

Precautions:

The appropriate amount of water should be selected according to the product requirements to control the slump and slump spread.

For the repair of bridge structures, new formwork should be used to ensure a beautiful appearance after demolding. The tools after construction should be cleaned with water in time for the next use.

During material transportation, rain prevention measures should be taken.

The material should be stored in a cool, dry place with a shelf life of 3 months. It can be used only after passing the re-inspection after the shelf life expires. During on-site use, it is strictly forbidden to add admixtures or admixtures to the material.

Packaging and storage:

Packaged in composite kraft paper bags, 25Kg/bag, shelf life 6 months;

It should be stored in a dry and ventilated room, with the packaging bags sealed, paying attention to moisture and frost prevention.

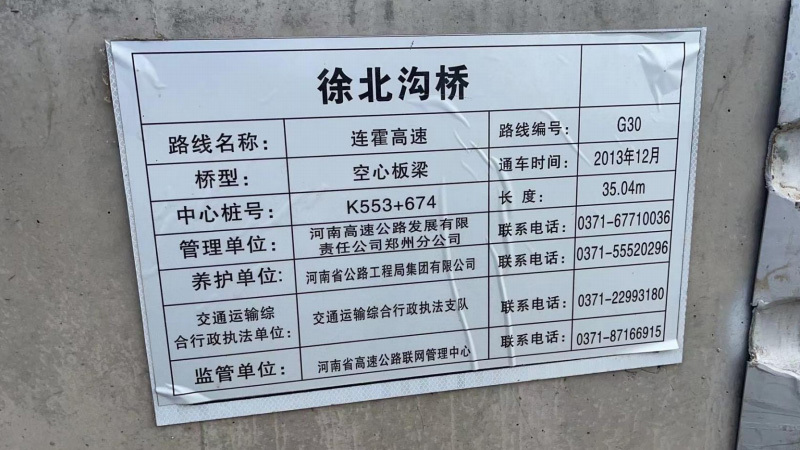

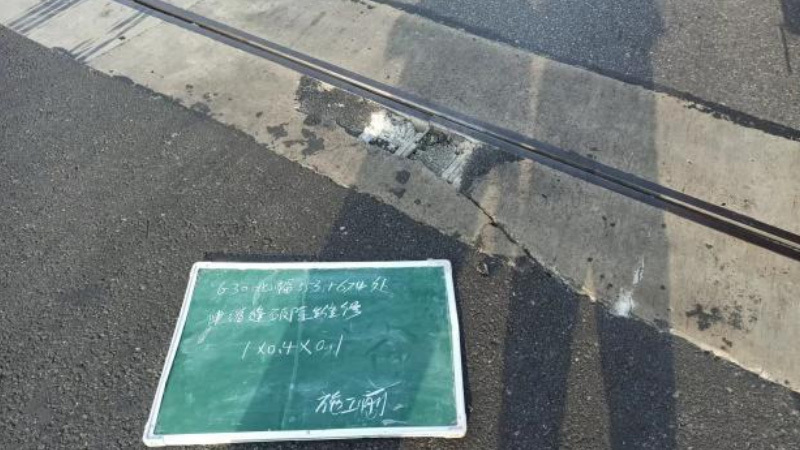

Expansion joint repair material project case 1: Lianhuo Expressway Zhongmu section expansion joint repair

Expansion joint repair material project case 2

Instructions for use of polymer rapid repair material

I. Product Introduction

The polymer rapid repair material developed and produced by Henan Zhengda Building Materials Co., Ltd. is a kind of ultra-early high-strength concrete repair material made of cement as the basic binder, high-strength materials as the main aggregate, and high-molecular polymer powder, admixtures, and anti-segregation materials. This product has the characteristics of small shrinkage and good self-compaction.

II. Product Purchase, Transportation, Storage and Use Instructions

1. When purchasing, pay attention to checking the inspection report on the vehicle and inspect the variety, quantity, production date, and factory number of the materials.

2. During transportation and storage, pay attention to moisture-proof and caking prevention. Store in a well-ventilated and dry place, protecting it from rain, moisture, sun, and frost.

3. When the ambient temperature is below 5℃, winter construction measures should be taken.

4. If there are any objections to the product quality, please provide timely feedback within 30 days from the date of product issuance. Our company has the right to refuse to handle quality complaints that exceed the nationally stipulated validity period.

5. Products should be stored separately by variety, batch number, and production date for FIFO (First-In, First-Out) management; the shelf life is 3 months. After the shelf life expires, the product should be re-inspected and pass before use.

6. During on-site construction, if the mixed materials in the forced mixer are not completely used, the mixer must be kept running to ensure the fluidity and workability of the polymer rapid repair material in the hopper.

7. If products from other manufacturers are used as substitutes, mixed, or submitted for inspection in place of Zhengda Building Materials Polymer Rapid Repair Material, our company has the right to pursue corresponding responsibilities for any resulting quality issues.

8. Users should strictly follow the "Product Preparation Precautions" in this manual. Our company is not responsible for quality problems caused by improper construction operations or arbitrary changes to material composition.

III. Product Preparation Precautions

1. Base Surface Treatment:

(1) Cleaning: First, remove the loose parts in areas with blistering, peeling, and cracks. For areas less than 3 mm deep, overly smooth areas, and areas with oil stains, roughen the surface. Roughening can be done using professional roughening equipment or manually using a pointed hammer.

(2) Cleaning: Remove floating dust and other debris from the base surface. Rinse thoroughly with high-pressure water, ensuring that the slurry is flushed out of the work area and prevented from flowing back.

(3) Wetting: After washing with water, keep the water on the work surface for a period of time to fully saturate the surface until it no longer absorbs water.

2. Construction Ratio

Dry Material (50kg): Water (6.0±0.25kg). To ensure uniform mixing, it is recommended that each batch not exceed 2 bags.

3. Construction Method

On-site mixing should use a horizontal shaft forced mixer (mixer motor power 3000w-4000w). The mixer speed should not be less than 45-80 rpm. For mixers with a capacity ≥300 liters, a 4 KW motor is recommended.

Before starting the mixer, weigh out 90% of the water, then add the cement-based dry material and mix for 3-5 minutes. Add the remaining 10% of the water and mix for 2-3 minutes until a fluid state is reached, then stop mixing. The mixed polymer rapid manhole cover repair material should be used within 20 minutes.

4. Curing

Cover the top surface of the repair material with plastic film, then cover the plastic film with burlap to maintain moisture. Under normal temperature conditions, curing can be completed after 3-4 hours. In winter, insulation measures should be taken, and the curing period should be extended appropriately.

Key words:

Bridge Expansion Joint Rapid Repair Compound

Previous Page:

Next page:

Message

Related Cases

Related Products