High-strength, non-shrinkage grout

Category:

Detailed description:

It is made of high-strength materials as aggregates, cement as a binder, and supplemented with high-flow, micro-expansion, and anti-segregation materials. A certain amount of water is added at the construction site, and after thorough mixing, it can be used. It is mainly used for secondary grouting of equipment foundations, reinforcement of beams, columns, and slabs, and road repair projects.

Product Features:

1. Early and high strength: Compressive strength can reach more than 30-50 Mpa in 1-3 days.

2. High self-flow: It can fill all gaps and meet the requirements of secondary grouting of equipment.

3. Micro-expansion: Ensure close contact between equipment and foundation, no shrinkage after secondary grouting. High bonding strength, the grip strength with round steel is not less than 6 Mpa.

4. Winter construction is possible: Outdoor construction is allowed at temperatures of -10℃.

5. Strong durability: This product is an inorganic binder material, and its service life is longer than that of the foundation concrete. Fatigue test shows that the strength has no significant change after 50 freeze-thaw cycles.

Application Range:

1. Suitable for grouting equipment foundations such as machine bases and anchor bolts.

2. Reinforcement, repair, strengthening of beams, slabs, columns, foundations, floors and roads of buildings.

3. Anchoring and structural reinforcement of anchor bolts and reinforcing bars can be performed.

4. Grouting of inserted column bases for steel structure columns and concrete columns.

5. Secondary grouting of fixed connections between steel structures (rails, steel frames, steel columns, etc.) and foundations.

Note: For other projects, the type of product can be selected according to the requirements of GB/T50448-2015 and the actual engineering needs.

Recommended Material Usage for Anchor Bolt Grouting:

|

Net distance between bolt surface and hole wall (mm) |

Recommended Grouting Material |

|

15-50 |

Ultra-high flow type, high flow type, high flow type |

|

50-100 |

Ultra-high flow type, high flow type, high flow type, fine stone type |

|

>100 |

Fine stone type |

Recommended Material Usage for Secondary Grouting:

|

Grouting layer thickness (mm) |

Recommended Grouting Material |

|

5-30 |

Ultra-high flow Type Ⅰ, high flow Type Ⅱ |

|

20-100 |

Ultra-high flow Type Ⅰ, high flow Type Ⅱ |

|

80-200 |

Ultra-high flow Type Ⅰ, high flow Type Ⅱ, high flow Type Ⅲ |

|

>200 |

Fine stone Type Ⅳ |

Note: For other projects, the type of product can be selected according to the requirements of GB/T50448-2015 and the actual engineering needs.

Construction Process:

1. Construction Preparation

◆ The construction site quality management should have corresponding construction technical standards, a sound quality management system, construction quality control and quality monitoring system. Before grouting, there should be a construction organization design or construction technique plan, which has been reviewed and approved.

◆ Before grouting, mixing equipment, grouting equipment, templates and maintenance items should be prepared.

◆ In addition to complying with the relevant provisions of the current national standard "Code for Construction Quality Acceptance of Concrete Structure Engineering" GB50204, the template support should also comply with the following provisions:

◆ During secondary grouting, the horizontal distance between the template and the equipment base should be controlled at about 100mm, and the top elevation of the template should not be lower than the upper surface of the equipment base by 50mm;

◆ When the concrete structure is remodeled and reinforced, the template support should leave sufficient grouting holes and vent holes. The diameter of the grouting holes should not be less than 50mm, and the spacing should not exceed 1000mm. The grouting holes and vent holes should be 50mm higher than the holes.

2. Mixing

◆ The mixing of cement-based grouting materials should be carried out according to the water consumption required by the product.

◆ Cement-based grouting materials should be mechanically mixed. When mixing, 2/3 of the total water should be added first and mixed for 3 minutes, then the remaining 1/3 of the water should be added and mixed until uniform. If the manufacturer has specific mixing requirements for the product, the mixing should be carried out according to its requirements.

◆ The mixing location should be close to the grouting construction location.

3. Anchor Bolt Grouting

◆ The construction process of anchoring anchor bolts should meet the corresponding requirements.

◆ When drilling anchor bolt holes, the horizontal deviation of the bolt holes should not be greater than 5mm, and the vertical deviation should not be greater than 5°. The bolt hole walls should be rough, and the inside of the bolt holes should be cleaned, and there should be no floating ash, oil stains, etc. Soak in water for 8-12h before grouting, and remove the accumulated water in the holes. When the ambient temperature is below 5℃, measures should be taken to preheat, and the temperature should be kept above 10℃.

◆ Remove oil stains and rust from the surface of the anchor bolts before grouting.

◆ Pour the mixed cement-based grouting material into the bolt holes, and adjust the position of the bolts as needed. Do not tamp during the grouting process, and appropriate tamping can be performed. The bolts should not be adjusted again after the grouting is completed.

◆ The upper surface of the grouting layer in the hole should be about 50mm below the surface of the foundation concrete.

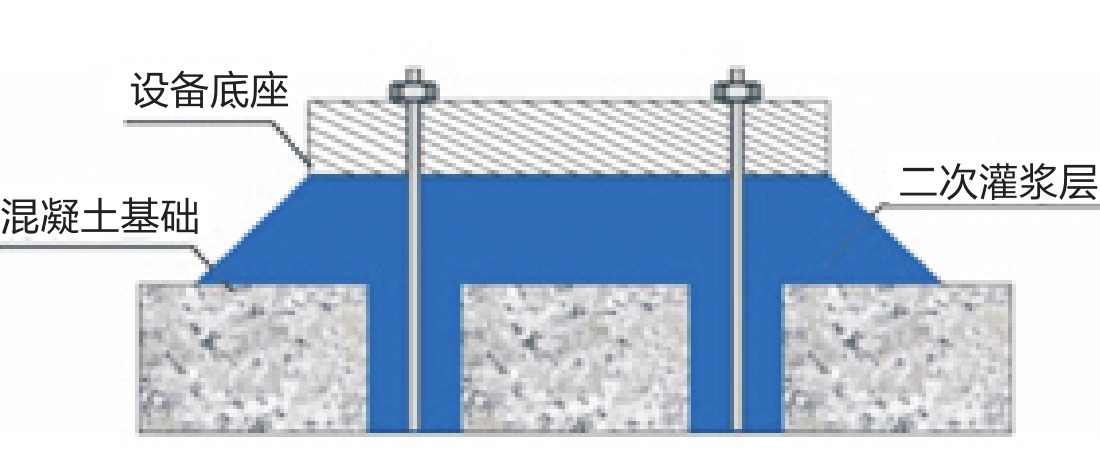

4. Secondary Grouting

◆ The secondary grouting method should be selected according to the actual situation. The process flow conforms to the corresponding requirements.

◆ Before grouting, the equipment base plate and concrete base surface in contact with the grouting material should be cleaned, and there should be no loose stones, floating slurry, floating ash, oil stains, wax, etc. 24 hours before grouting, the surface of the base concrete should be moistened, and the accumulated water should be cleaned 1 hour before grouting.

◆ During secondary grouting, grouting should be carried out from one side until it overflows from the other side, and grouting should not be carried out from both sides simultaneously. After the grouting starts, it must be continuous, and the grouting time should be shortened as much as possible.

◆ When the track foundation or grouting distance is long, construction can be carried out in sections according to the actual project conditions.

◆ Vibration is strictly prohibited during the grouting process. If necessary, a grouting booster can be used to push the grouting material along the bottom in the direction of the slurry flow. It is strictly prohibited to push from the middle and upper parts of the grouting layer.

◆ After the equipment foundation grouting is completed, it is advisable to cut a 45° bevel outward along the edge of the base plate 3~6 hours after grouting. (Figure 1)

5. Concrete structure renovation and reinforcement grouting

◆ The concrete surface in contact with the cement-based grouting material should be roughened.

◆ For the repair of concrete structural defects, loose concrete should be removed to expose the steel bars, and the edges of the repair area should be cut vertically to a depth of no less than 20mm.

◆ Before grouting, remove all stones, dust, or other debris, and moisten the base concrete surface.

◆ Pour the evenly mixed grouting material into the mold and tap the mold appropriately.

◆ When the grouting layer thickness is greater than 150mm, relevant measures should be taken to prevent temperature cracks.

6. Winter Construction

◆ When the average daily temperature is below 5℃, winter construction should be carried out in accordance with the following requirements:

◆ Measures should be taken to preheat the base surface before grouting to keep its temperature above 10℃, and accumulated water should be removed;

◆ Warm water not exceeding 65℃ should be used to mix the cement-based grouting material, and the molding temperature of the slurry should be above 10℃;

If early-strength and anti-freezing products are used, follow the Description strictly.

◆ Curing: Before freezing, the compressive strength of the cement-based grouting material should not be less than 5Mpa.

7. High-temperature climate environment construction

◆ When the temperature of the grouting part is greater than 35℃, construction should be carried out in accordance with the high-temperature climate environment and meet the following requirements:

◆ 24 hours before grouting, take measures to prevent the grouting part from being exposed to direct sunlight or other thermal radiation;

◆ Take appropriate cooling measures, and the temperature of the concrete foundation and equipment base plate in contact with the cement-based grouting material should not exceed 35℃;

◆ The molding temperature of the slurry should not exceed 30℃;

◆ Moisture-retaining curing measures should be taken promptly after grouting.

8. Normal temperature curing

◆ During grouting, the average daily temperature should not be lower than 5℃. After grouting is completed, the exposed part should be sprayed with a curing agent or covered with a plastic film, and covered with wet straw bags to keep it moist. When using film coverage, the exposed surface of the cement-based grouting material should be covered tightly, and there should be condensed water inside the plastic film. When the surface of the grouting material is inconvenient to water, a curing agent can be sprayed.

◆ The exposed part of the grouting should be kept moist, and the curing time should not be less than 7 days.

◆ When fast-setting and fast-hardening cement-based grouting materials are used, the curing measures should be implemented according to the product requirements.

9. Winter construction and maintenance

◆ In winter construction, when the project has no special requirements for strength growth, the exposed part should be covered with plastic film and insulation material immediately after grouting. The initial curing temperature should not be lower than 5℃. Do not water during curing under negative temperature conditions.

◆ When the temperature difference between the surface temperature of the cement-based grouting material and the ambient temperature is greater than 20℃ after demolding, insulation materials should be used for covering and curing.

◆ If the ambient temperature is lower than the low construction temperature required by the cement-based grouting material or the strength growth needs to be accelerated, artificial heating curing can be used; the curing measures must comply with the relevant provisions of the national standard "Construction Engineering Winter Construction Regulations" JGJ104.

Key words:

High-strength, non-shrinkage grout

Message

Related Cases

Related Products