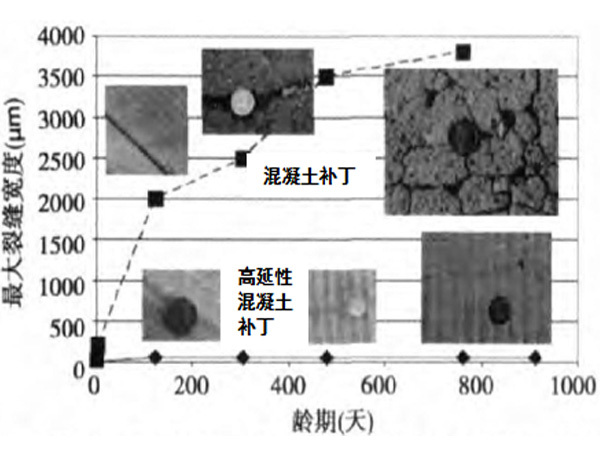

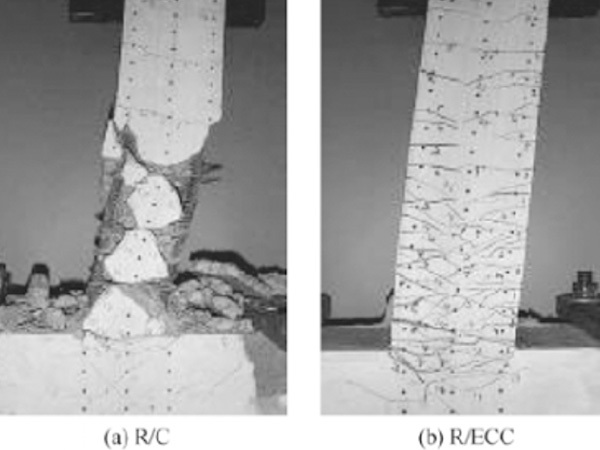

Comparison of Repair Effects of High-Ductility Concrete and Ordinary Concrete

High-ductility concrete

Category:

Detailed description:

Introduction: High-Ductility Concrete (HDC) is a fiber-reinforced concrete with ultra-high deformability and excellent crack control capabilities. Invented by Professor Victor Li of the University of Michigan, it differs from ordinary fiber-reinforced concrete. Its fiber incorporation is based on the design of micromechanics and fracture mechanics, thus also known as designable cement-based composite materials (ECC). The key core material of high-ductility concrete is the fiber, because the fiber's tensile bond enables the concrete to exhibit high ductility. The addition of fibers limits crack width, improves tensile, flexural, and shear strength, and significantly improves its ductility, toughness, fatigue resistance, and impact resistance. Its ultimate tensile strain is typically greater than 3%, forming numerous fine cracks less than 100μm wide during tensile loading, changing the characteristic of traditional cement-based materials that are prone to brittle failure, and exhibiting ultra-high energy dissipation capacity and deformability.

Demonstration of High-Ductility Concrete Deformability and Crack Control Effects

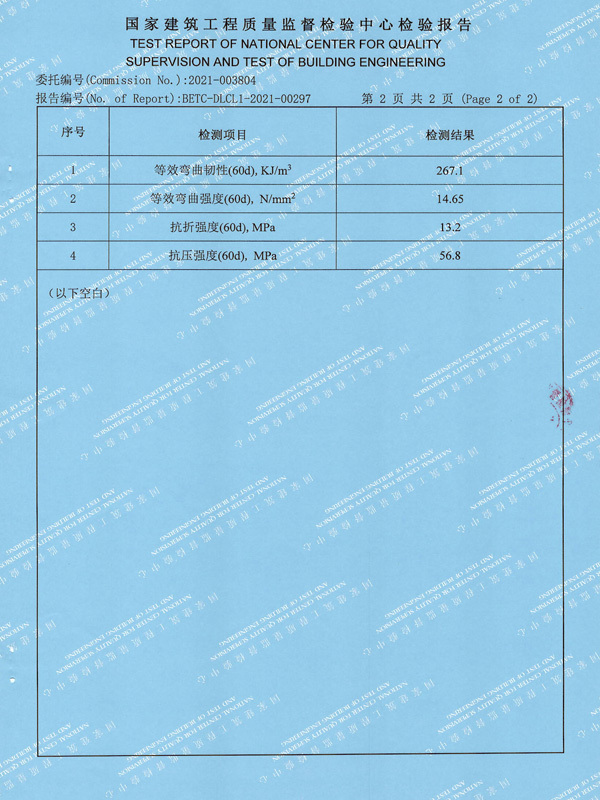

Product Performance: Our company, through optimized design and proportions, uses a larger amount of fly ash and other materials without compromising product performance, reducing cement usage, following the principles of green, environmentally friendly, and sustainable development, while reducing costs. The developed high-ductility concrete products have compressive strengths in the range of 50-100 MPa, flexural strength exceeding 20 MPa, equivalent flexural strength above 12 MPa, and ultimate tensile strain in the range of 3% to 10%, with significant multi-crack phenomena. The mechanical properties of the developed high-ductility concrete are far superior to existing products on the market. Also, based on product performance and application, it can be divided into several series:

1) Masonry structure reinforcement material

2) Concrete structure reinforcement material

3) Road and bridge surface repair material

4) Expansion joint pouring material

5) Grouting material

6) Self-consolidating material

7) Sprayable material 8) High-temperature resistant material

Table 1 High-Ductility Concrete Performance Index Establishment

|

Product Grade |

Flexural Strength (MPa) |

Equivalent Flexural Toughness |

Ultimate Tensile Strain |

Compressive Strength (MPa) |

Applications |

|

High-Ductility Concrete |

≥12 |

≥160 |

/ |

30-100 |

Masonry Structure Reinforcement |

|

Ultra-High Ductility Concrete |

≥14 |

≥240 |

1-3 |

30-100 |

Concrete Structure Reinforcement, High-Durability Structure Repair |

|

Ultra-High Ductility ECC |

≥16 |

≥320 |

3-8 |

30-100 |

Seismic Coupled Beams, Core Node Area Pouring |

Applications:

1. High-Ductility Concrete Reinforcement of Masonry Structures

By applying a high-ductility concrete surface layer to the surface of masonry structures, its excellent bonding performance with the masonry surface allows the high-ductility concrete surface layer and the masonry to become a whole, sharing the load. It utilizes its high toughness, high strength (tensile), high crack resistance, and high damage tolerance to improve the load-bearing capacity, ductility, and crack resistance of the masonry structure. It effectively improves the integrity of masonry buildings. Buildings reinforced with this material can withstand a magnitude 10 earthquake, and over 10,000 buildings have already been reinforced. This method is characterized by its high strength, efficiency, ease of construction, and minimal damage to the original structure. It is easy to promote and can be widely used in earthquake resistance of houses, house reinforcement, renovation of dilapidated houses, cultural relic protection, village protection, and renovation of historical and architectural landscapes.

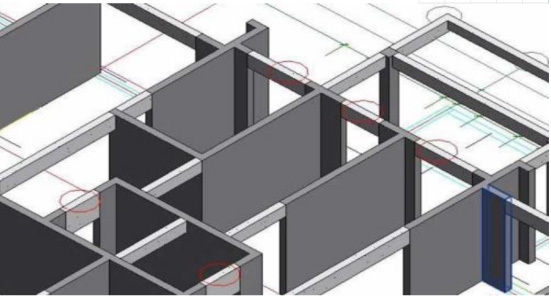

2. High-Ductility Concrete Reinforcement of Concrete Structures

High-ductility concrete has many advantages, including light weight, good toughness, high strength, and good crack control, making it one of the most frequently used construction materials in various engineering projects. Its application in the reinforcement of brick-concrete structures in old residential areas is also a reinforcement technology with good application prospects.

(a) Without High-Ductility Concrete

(b) High-Ductility Concrete Formwork Reinforcement

High-Ductility Concrete Reinforcement of Old Buildings

3. Repair of Easily Damaged Structures

The multi-crack characteristic of high-ductility concrete under tension and bending can prevent external erosion of the structure's interior and improve its durability. Its good toughness and energy dissipation capacity allow it to withstand high stress and repeated loads without being easily damaged. Therefore, high-ductility concrete has great advantages in applications such as roads, bridges, tunnels, dams, and aqueducts, where high structural durability is required.

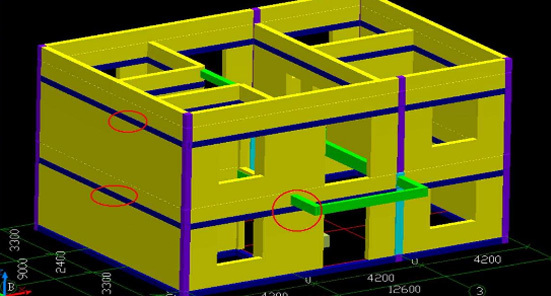

4. High-Ductility Concrete Used for Seismic Coupled Beams and Core Node Areas

Applying high-ductility concrete to key parts of a structure can significantly improve its seismic resistance. For example, using high-ductility concrete to replace ordinary concrete in the coupled beams of high-rise buildings can effectively prevent premature brittle shear failure of the coupled beams and significantly improve the energy dissipation capacity of the coupled beams, improving the load-carrying capacity and deformability of the components, thus solving the problem of exceeding the shear-pressure ratio. In Osaka, Japan, the 60-story Kitahama building used high-ductility concrete in its core, greatly improving its seismic resistance.

Reinforced Concrete Shear Wall Structure Coupled Beam

Comparison of Seismic Performance of Ordinary Concrete Nodes (Left) and High-Ductility Concrete Nodes (Right)

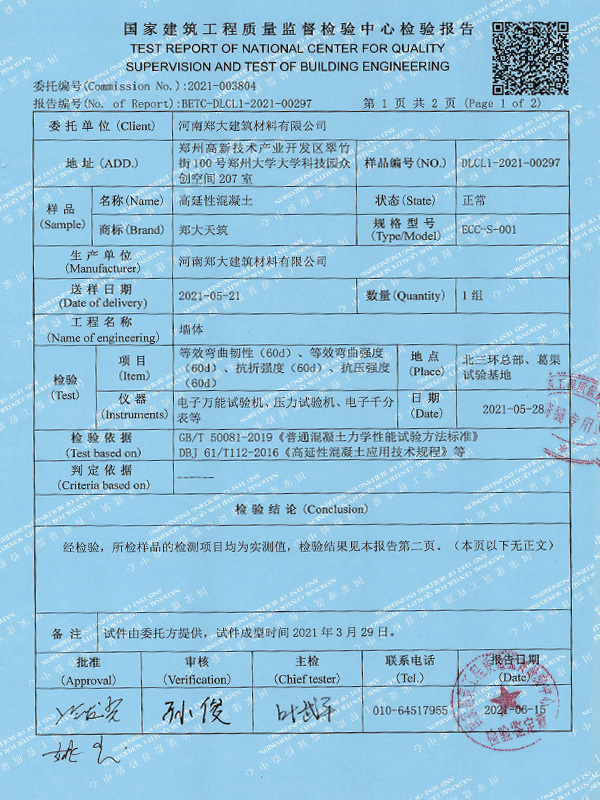

Test Report:

Key words:

High-ductility concrete

Previous Page:

Message

Related Cases

Related Products